GFRC – Glass Fiber Reinforced Concrete

About GFRC

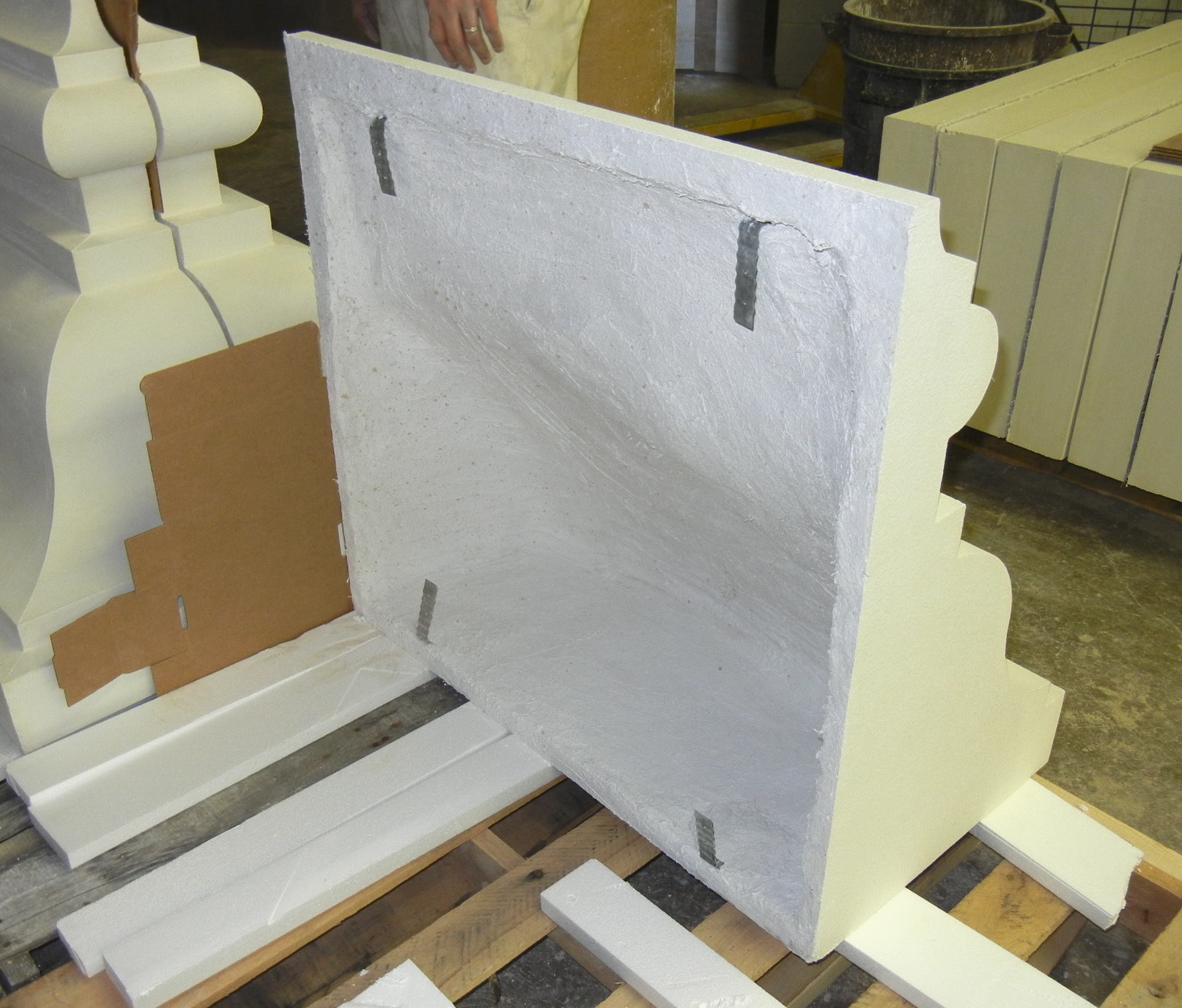

GFRC is concrete that uses glass fibers for reinforcement instead of steel. It is typically cast in a thin section of 1/2″ to 3/4″ in thickness. Since the fibers cannot rust like steel, there is no need for a protective concrete cover thickness to prevent rusting. With the thin, hollow construction of GFRC products, they can weigh a fraction of the weight of traditional precast concrete. GFRC is a composite of cement, glass fibers, aggregates and polymers. It has the look and feel of traditional solid precast and can be used in conjunction with solid precast to meet the projects design criteria.

How GFRC Can Be Used

GFRC can be used wherever a light, strong, weather resistant, attractive and fire retardant material is required.

- GFRC can be used in manufacturing architectural products such as window surrounds, column covers, cornices, brackets, quoins, pilasters and fireplace surrounds.

Glass Fiber Reinforced Concrete Strength

As an engineered material, the properties of GFRC can vary depending upon mix design, glass content and production methods. Glass fiber used in quality GFRC has a higher tensile strength than steel. As a general rule, the higher the fiber content, the higher the strength. A typical mix with 3% glass fiber has a compressive strength of 6,000 to 8,000 psi. The biggest difference between solid cast and GFRC is that GFRC has significantly higher flexural properties than solid cast products.

GFRC Durability

Glass fiber reinforced concrete has been tested both by accelerated aging tests in the laboratory and in real life installations. GFRC can be expected to last as long as pre-cast concrete. In many environments, as when exposed to salt spray or high moisture, the GFRC can be expected to perform better, as there is no steel reinforcement to corrode. Since the surface of GFRC is a Portland concrete, it weathers much as a quality architectural pre-cast concrete would.

Advantages of GFRC

• Made of minerals and will not burn. In addition, the nature of concrete acts likes a thermal regulator when exposed to flame. GFRC not only will not burn, but it also protects the materials behind it from the heat of the flame.

• Relatively light in weight compared to traditional cast concrete. Its installation is quick and relatively easy. GFRC products typically reduce the amount of anchors and fasteners needed to attach the stone. Many pieces can be handled by one installer while the same profile in solid cast would require multiple installers or lifting equipment.

• Can be cast to virtually any shape straight or radius.

• Lightweight

• Classic Stone Creations GFRC, thin yet strong, weighs 70-85% less than solid concrete. This makes it easier and faster to install and reduces the load on the buildings structure. The lighter weight and stronger material also saves transport costs, allows more design freedom and, by using less material, reduces environmental impact.

•Durable

•Classic Stone Creations GFRC lasts. It is less susceptible to weather erosion and more freeze thaw resistant than conventional concrete. The use of glass fibers for reinforcement rather than steel means it cannot rust and can even be used in salt water and in marine environments.

•Beautiful

•Classic Stone Creations GFRC provides the look and feel of natural stone or architectural precast. We can manufacture GFRC in our “Classic” cast concrete mixture or our “Limestone” mixture which allows the designer more freedom in shape, color and texture than any material. GFRC can be manufactured in any of our standard colors, custom colors and a variety of finishes from smooth, acid washed, antiqued or distressed.

Contact Classic Stone Creations for any questions that you may have regarding GFRC.